Stainless hlau kas fes Sintered ntsiav tshuaj

Cov kev qhia siv tau

1. Nias cov hmoov kas fes nrog lub tamper

2. Muab tso rau hauv qhov loj me ntawm cov dej sib cais mesh

3. Muab tus kov ntawm lub tshuab kas fes rau ntawm lub taub hau brewing

4. Saib cov kua

Vim li cas thiaj siv lub network faib dej thib ob?

Qhov thib ob dej faib net zoo cais cov kas fes hmoov thiab lub taub hau brewing kom nws huv si

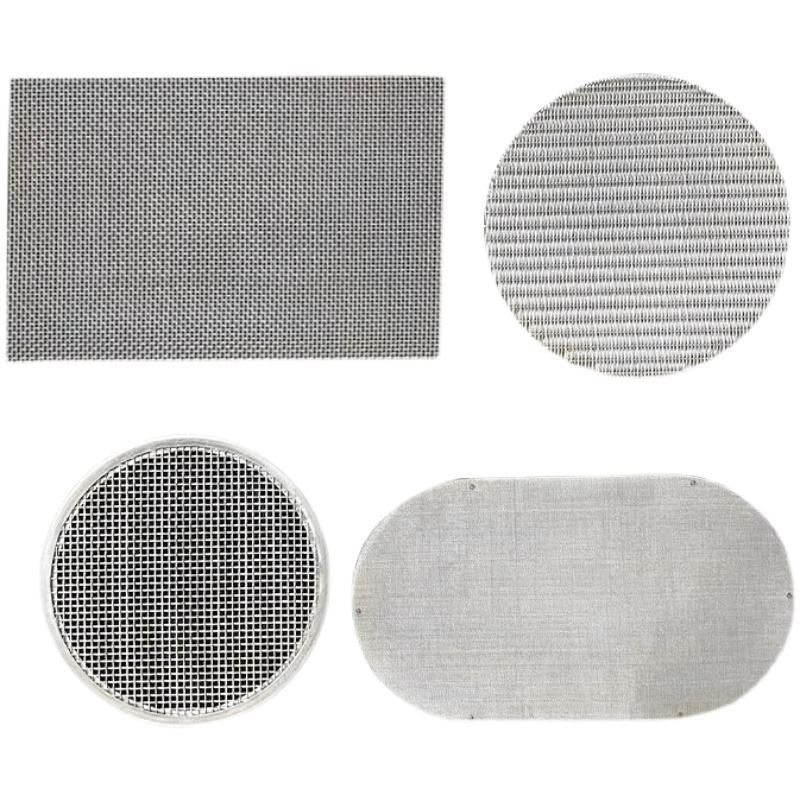

Cov yam ntxwv ntawm sintered mesh

1. Lub zog muaj zog thiab zoo rigidity: Nws muaj lub zog txhua yam thiab compressive zog, ua haujlwm zoo, vuam thiab sib dhos ua haujlwm, thiab siv tau yooj yim.

2. Uniform thiab ruaj khov precision: Uniform thiab zoo pom kev ua tau zoo tuaj yeem ua tiav rau txhua qhov kev pom tseeb, thiab cov mesh tsis hloov thaum siv.

3. Kev siv dav hauv ib puag ncig: Nws tuaj yeem siv rau hauv qhov chaw kub ntawm -200 ℃ ~ 600 ℃ thiab pom cov kua qaub thiab alkali ib puag ncig.

4. Kev ua tau zoo ntawm kev tu: zoo countercurrent tu nyhuv, tuaj yeem siv ntau zaus, thiab muaj lub neej ua haujlwm ntev (tuaj yeem ntxuav los ntawm cov dej countercurrent, lim, ultrasonic, melting, ci, thiab lwm yam).

Sintering ntau lawm txheej txheem

1. Tsawg kub ua ntej kub kub theem.Nyob rau theem no, qhov rov qab ntawm cov hlau, volatilization ntawm adsorbed gas thiab noo noo, decomposition thiab tshem tawm ntawm kev tsim tus neeg sawv cev nyob rau hauv lub compact mas tshwm sim;

2. Nruab nrab kub cua sov sintering theem.Nyob rau theem no, recrystallization pib tshwm sim.Hauv cov khoom, cov nplej deformed tau rov qab los thiab rov ua dua tshiab rau hauv cov nplej tshiab.Nyob rau tib lub sijhawm, cov oxides ntawm qhov chaw raug txo, thiab cov khoom sib txuas ua rau lub caj dab sintered;

3. Kub kub preservation ua tiav sintering theem.Diffusion thiab ntws hauv cov theem no tau ua tiav thiab ze rau kev ua tiav, tsim ntau qhov chaw kaw qhov pores, thiab txuas ntxiv mus, kom lub pore loj thiab tag nrho cov pores raug txo, thiab qhov ceev ntawm lub cev sintered yog ho. nce.